Exploring the Versatility of Petroleum Resin: Primary Applications Unveiled

2024-03-18

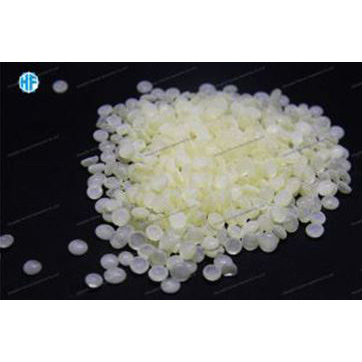

Petroleum resin, a versatile synthetic resin derived from petroleum feedstocks, finds its way into a myriad of industries and applications due to its unique properties and capabilities. From adhesives and coatings to inks and rubber compounds, petroleum resin plays a pivotal role in enhancing performance and functionality across various sectors. In this blog, we'll delve into the primary applications of petroleum resin and uncover its diverse range of uses.

Adhesives and Sealants:

One of the primary applications of petroleum resin is in the formulation of adhesives and sealants. Petroleum resin acts as a crucial binder, providing excellent adhesion properties that bond various substrates together. Whether in construction, automotive, or packaging, petroleum resin-based adhesives and sealants offer strength, durability, and resistance to environmental factors, making them indispensable in a wide range of bonding applications.

Coatings and Paints:

Petroleum resin serves as a key ingredient in coatings and paints, where it enhances performance and durability. Its ability to improve adhesion, gloss, and scratch resistance makes it an ideal choice for formulating protective coatings for metal, wood, and plastic surfaces. In addition, petroleum resin-based paints exhibit excellent weathering resistance, color retention, and chemical resistance, making them suitable for outdoor applications and harsh environments.

Inks and Printing:

In the printing industry, petroleum resin plays a crucial role in the formulation of inks for various printing processes, including flexographic, gravure, and screen printing. Petroleum resin-based inks offer fast drying times, excellent color dispersion, and adhesion to a wide range of substrates, such as paper, cardboard, and plastics. These inks are widely used in packaging, labels, magazines, and commercial printing applications, where vibrant colors and sharp graphics are essential.

Rubber Compounding:

Petroleum resin is extensively used in the rubber industry for compounding applications, particularly in tire manufacturing. It acts as a tackifier, reinforcing agent, and processing aid in rubber compounds, improving tackiness, adhesion to substrates, and overall performance of the final product. Petroleum resin-based rubber compounds exhibit excellent resilience, abrasion resistance, and weathering resistance, making them ideal for automotive tires and industrial applications.

Other Applications:

Beyond the aforementioned sectors, petroleum resin finds applications in a multitude of other industries and products:

- Construction: In construction, petroleum resin is used in waterproofing membranes, caulks, and sealants to enhance adhesion and durability.

- Electronics: It is utilized in the encapsulation of electronic components and as a binder in potting compounds and coatings for circuit boards.

- Textiles: Petroleum resin is employed in textile coatings and finishes to improve abrasion resistance, water repellency, and wrinkle resistance.

- Personal Care: In personal care products, it serves as a binder in cosmetics, hair styling products, and fragrances.

Conclusion:

Petroleum resin's versatility and adaptability make it an indispensable ingredient in numerous industries and applications. Whether as a bonding agent in adhesives, a protective coating in paints, an ink vehicle in printing, or a reinforcing agent in rubber, petroleum resin plays a vital role in enhancing performance, functionality, and durability across diverse sectors. As industries continue to innovate and evolve, petroleum resin remains a cornerstone of modern manufacturing, driving progress and efficiency in the ever-changing industrial landscape.