Materials Used in the Construction of Multilayer Boards

2024-05-24

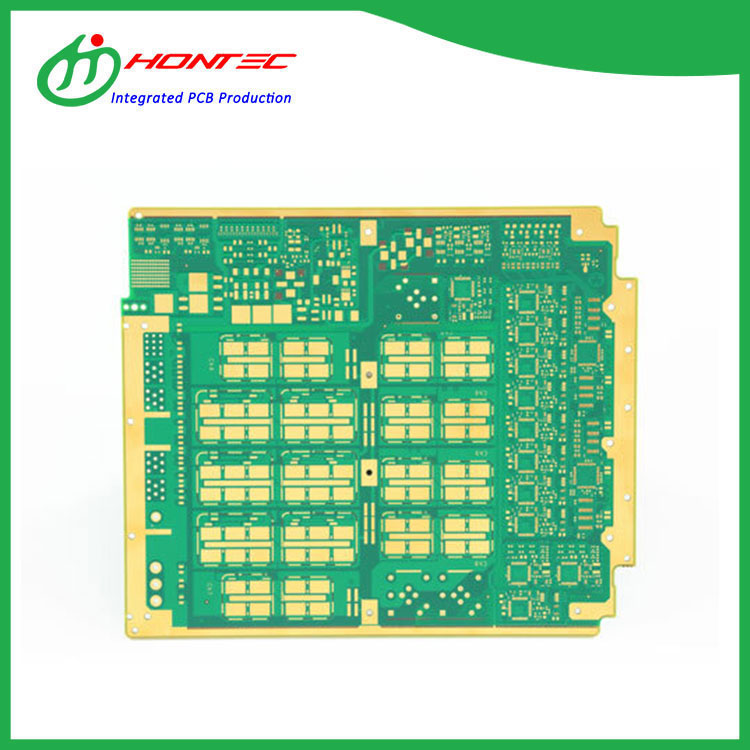

Multilayer boards, also known as multilayer PCBs (printed circuit boards), are an integral part of modern electronics. They enable the creation of complex circuitry by stacking multiple layers of conductive and non-conductive materials. In this blog, we'll explore the materials commonly used in the construction of multilayer boards.

1. Conductive Materials

The conductive layers in multilayer boards are typically made of copper. Copper is an excellent conductor of electricity, and its high conductivity allows for efficient signal transmission and low resistance. Copper foils with various thicknesses are laminated onto the non-conductive substrates to form the conductive layers.

2. Non-Conductive Substrates

The non-conductive substrates in multilayer boards provide the structural support and hold the conductive layers in place. The most commonly used substrate material is FR-4 (flame retardant grade 4), which is a type of epoxy resin-based glass fiber composite. FR-4 is chosen for its excellent electrical, mechanical, and thermal properties, as well as its cost-effectiveness.

Other non-conductive substrate materials include polyimide, Teflon, and ceramic. These materials offer specific advantages, such as higher thermal stability or better chemical resistance, and are used in specialized applications.

3. Dielectric Materials

Dielectric materials are used to separate the conductive layers and prevent short circuits. They are typically made of organic resins, such as epoxy or polyimide, which are impregnated with glass fibers or fillers to improve their mechanical strength and dimensional stability. The choice of dielectric material depends on the specific requirements of the application, such as electrical performance, heat dissipation, and environmental factors.

4. Solder Mask

Solder mask is a protective coating applied to the surface of the multilayer board. It covers the conductive traces and vias, preventing solder bridges and short circuits during assembly. Solder mask is typically made of a liquid photoresist material that is applied, exposed to UV light, and then cured to form a hard, protective layer.

5. Silkscreen

Silkscreen is an ink-based material used to print legends, component references, and other markings on the surface of the multilayer board. It provides visual identification and aids in the assembly and troubleshooting of the PCB. Silkscreen is applied after the solder mask and is typically made of an epoxy-based ink that is screen-printed onto the board.

Conclusion

Multilayer boards are constructed using a combination of conductive, non-conductive, and protective materials. Copper is the most commonly used conductive material, while FR-4 is the most popular non-conductive substrate. Dielectric materials separate the conductive layers, solder mask provides protection during assembly, and silkscreen provides visual identification. Understanding the materials used in multilayer board construction can help you make informed decisions when designing and manufacturing your PCBs.