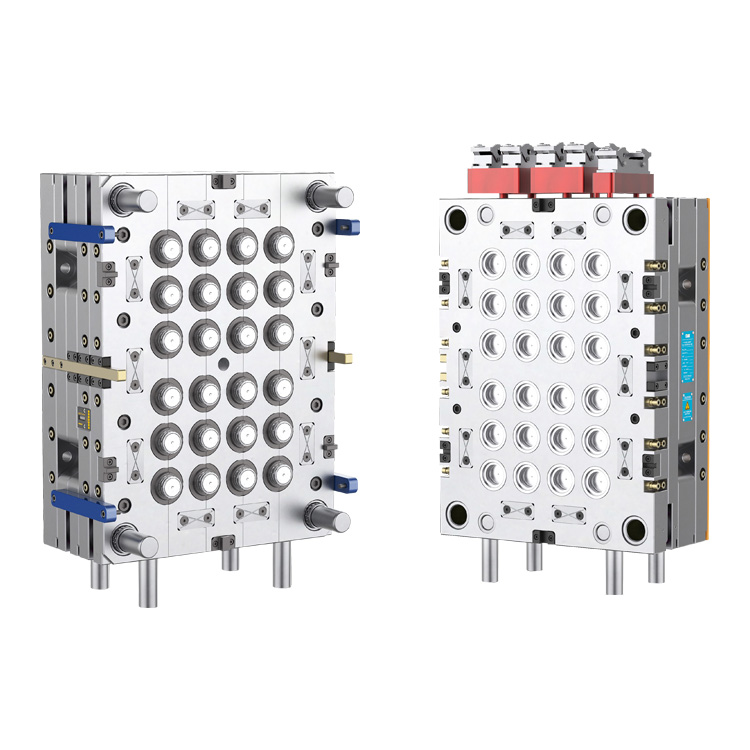

Precision Unleashed: Design Features of an Efficient 24-Cavity Cap Mold

2024-01-17

Introduction:

In the realm of injection molding, efficiency and precision are paramount, especially when it comes to high-volume production of caps. A 24-cavity cap mold is a testament to the marriage of intricate design and cutting-edge technology. This blog delves into the key design features that make a 24-cavity cap mold efficient and effective in delivering precise, high-quality caps at scale.

1. Multi-Cavity Layout:

The hallmark of a 24-cavity cap mold is its multi-cavity layout. This design feature allows for the simultaneous production of 24 caps in each molding cycle, significantly increasing production efficiency and output.

2. Symmetrical Cavity Arrangement:

Symmetry in cavity arrangement is crucial for ensuring balanced filling and cooling across all cavities. A well-balanced design minimizes the risk of variations in cap dimensions and enhances overall product consistency.

3. Runner and Gate System:

The runner and gate system is meticulously designed to facilitate the flow of molten material into each cavity. Efficient gating ensures uniform filling, minimizing the chances of defects like short shots or variations in cap weight.

4. Optimized Cooling Channels:

Efficient cooling is essential for maintaining consistent cycle times and preventing issues like warping or shrinkage. The design incorporates strategically placed cooling channels to ensure uniform temperature distribution throughout the mold.

5. Hot Runner System:

Many 24-cavity cap molds employ a hot runner system to eliminate the need for runners and reduce material wastage. This design feature contributes to cost savings and environmental sustainability while improving overall production efficiency.

6. Quick Changeover Features:

The design may incorporate features that facilitate quick mold changeovers, allowing for flexibility in production and the ability to switch between different cap designs with minimal downtime.

7. Ejection System:

An efficient ejection system is crucial for the smooth removal of molded caps from the mold. The design features robust ejection mechanisms, such as ejector pins or sleeves, ensuring reliable and swift ejection after each molding cycle.

8. Venting System:

Proper venting is essential to prevent air entrapment during the molding process. The design incorporates venting systems in strategic locations to allow the escape of air and ensure complete cavity fill, reducing the risk of defects.

9. Quality Control Measures:

The mold design may include provisions for quality control measures, such as sensors or cameras, to monitor and detect any variations in the molding process. This ensures early identification of issues and maintains the production of high-quality caps.

10. Durability and Wear Resistance:

Materials with high durability and wear resistance, such as hardened steel alloys, are often chosen for critical components like core and cavity inserts. This design choice enhances the mold's lifespan and reduces the need for frequent maintenance.

Conclusion:

A well-designed 24-cavity cap mold is a testament to the synergy of engineering expertise and technological innovation. The intricacies of multi-cavity layout, optimized cooling, efficient ejection systems, and precision injection molding collectively define the efficiency and effectiveness of these molds. As industries continue to demand high-volume production with uncompromised quality, the evolution of design features in 24-cavity cap molds remains pivotal in shaping the future of injection molding technology.