Safety First: Exploring Crucial Safety Features in Industrial Crusher Machines

2023-11-06

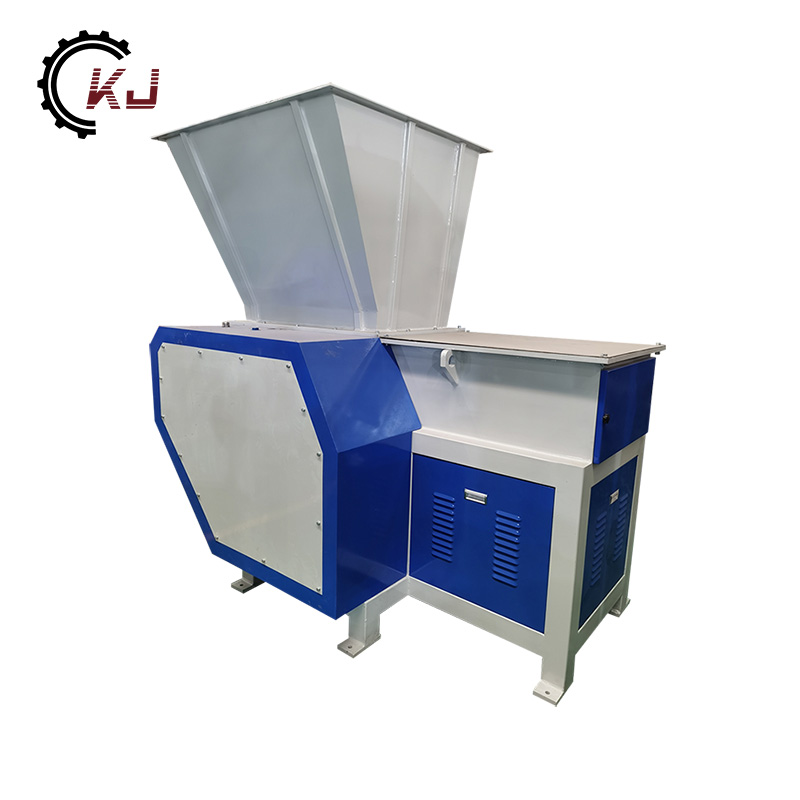

In the world of industrial processing and material reduction, safety is paramount. Industrial crusher machines, with their powerful crushing capabilities, are essential tools in various industries. Ensuring the safe operation of these machines is a top priority. In this blog, we will delve into the safety features incorporated into the design of industrial crusher machines and their vital role in protecting both workers and equipment.

Safety in Industrial Crusher Machines

The robust design and functionality of industrial crusher machines come hand in hand with safety considerations. These machines are engineered to handle challenging materials and large-scale processes, and safety features are integrated to mitigate risks. Here are some of the key safety features commonly incorporated into the design of industrial crusher machines:

1. Emergency Stop Button: Industrial crusher machines are equipped with an emergency stop button that provides an immediate and rapid shutdown in case of an emergency or dangerous situation. This feature ensures that the machine can be stopped at any moment to prevent accidents.

2. Safety Guards and Barriers: Many crusher machines are equipped with safety guards and physical barriers to prevent operators from coming into contact with moving or hazardous parts of the machine during operation.

3. Lockout/Tagout Systems: Lockout/tagout (LOTO) systems are integrated into the machine's design to provide a way to isolate energy sources and lock out the equipment during maintenance or repair, preventing unintended startup.

4. Access Control: Access to certain parts of the machine, such as the crushing chamber or moving components, may be restricted and controlled to prevent unauthorized access and reduce the risk of accidents.

5. Automatic Overload Protection: Some crusher machines are equipped with automatic overload protection that can detect excessive loads and shut down the machine to prevent damage or injury.

6. Safety Labels and Signage: Clear and conspicuous safety labels and signage are often affixed to the machine to provide operators with essential safety information and guidelines for operation.

7. Emergency Procedures: Manufacturers provide guidance on emergency procedures and safe operation in the machine's user manual. This includes instructions for dealing with common issues and potential safety risks.

8. Dust Control Systems: Dust and particulate matter can pose respiratory and fire hazards. Crusher machines may include dust control systems that reduce the release of airborne particles and improve air quality in the working environment.

9. Vibration and Noise Control: Crusher machines that produce excessive vibration or noise may be equipped with vibration isolators or noise-reducing measures to protect operators from excessive exposure to these elements.

10. Safety Interlocks: Certain operations or access points on the machine may be equipped with safety interlocks that prevent the machine from operating when specific conditions are not met or when safety barriers are open.

Key Considerations:

- Operator Training: Adequate training and familiarization with the machine's safety features and proper operation are essential to ensure safety.

- Routine Maintenance: Regular maintenance and inspection of safety features are crucial to identify and address any potential issues.

- Safety Compliance: Crusher machines should meet safety standards and regulations specific to the industry and location in which they are used.

- Emergency Response: Emergency response plans should be in place, and operators should be familiar with procedures in the event of an accident or emergency.

Conclusion

Safety is a fundamental aspect of the design and operation of industrial crusher machines. Manufacturers and operators alike prioritize safety features to protect workers and equipment. These features play a pivotal role in ensuring that crusher machines can be used effectively and securely in various industries. By adhering to safety guidelines, operators can harness the power and capabilities of crusher machines while maintaining a safe and productive working environment.