The Advantages of Precast Concrete Moulds in Efficient Construction

2025-02-19

In the evolving world of construction, time, cost, and quality are key factors that influence the success of any project. As builders look for ways to optimize processes and improve results, precast concrete moulds have become an essential tool. These moulds are not only efficient in producing high-quality components but also bring a host of other benefits that make them a go-to solution for a variety of building projects. Let’s explore the advantages of using precast concrete moulds and why they are revolutionizing the construction industry.

What Are Precast Concrete Moulds?

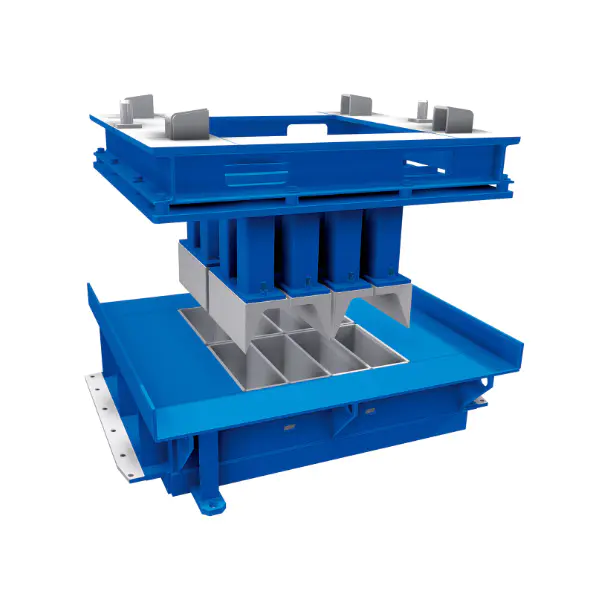

Precast concrete moulds are forms that are used to cast concrete in controlled factory settings. These moulds are often made from durable materials like steel or fiberglass and come in a variety of shapes and sizes. Once the concrete is poured into the mould, it is allowed to cure before being transported to the construction site for installation.

Precast concrete moulds can be customized to produce virtually any type of concrete product, from basic slabs and beams to more complex architectural components. Their versatility, efficiency, and cost-effectiveness make them a preferred choice for builders looking to streamline the construction process.

Key Advantages of Precast Concrete Moulds

1. High-Quality Concrete Products

The controlled environment in which precast concrete is poured and cured results in products of exceptional quality. Precast concrete components made from these moulds are less likely to have defects such as cracks or air pockets. The quality control process ensures that each piece meets the required specifications, making precast concrete an ideal choice for critical applications where strength and durability are essential.

2. Reduced On-Site Construction Time

One of the main advantages of using precast concrete moulds is the reduction in construction time. Precast elements are manufactured off-site while other construction activities are taking place, allowing for faster overall project timelines. Once the precast components arrive on-site, they can be quickly installed, minimizing downtime and accelerating the completion of the project.

3. Cost-Effectiveness

Precast concrete moulds help reduce material waste and improve cost efficiency in the production process. Since these moulds can be reused multiple times, they offer an excellent return on investment. Additionally, the quicker construction timeline and reduced labor costs contribute to overall project savings. The consistent quality of precast concrete also reduces the need for costly repairs and maintenance in the future.

4. Design Flexibility and Aesthetic Appeal

Precast concrete moulds offer a high degree of design flexibility. Whether you're looking to create basic structural components or more intricate decorative elements, these moulds can be tailored to meet specific design needs. Precast concrete can be finished in a variety of ways, from smooth and polished surfaces to textured and patterned designs. This versatility allows for both functional and aesthetically pleasing results, making it an excellent choice for both commercial and residential projects.

5. Sustainability

In today's construction industry, sustainability is more important than ever. Precast concrete is an environmentally friendly option due to its energy-efficient production process and the ability to reuse moulds. Additionally, concrete is highly durable and energy-efficient, helping to reduce the environmental impact over the lifespan of the building. Precast concrete components can also be recycled at the end of their use, further contributing to sustainability goals.

Common Uses of Precast Concrete Moulds

Precast concrete moulds are used in a broad range of applications, including:

- Residential Construction: Precast walls, floors, and ceilings provide efficient and cost-effective solutions for home builders.

- Commercial Buildings: Precast facades, structural beams, and flooring are commonly used in office buildings, shopping malls, and industrial facilities.

- Infrastructure: Components such as bridges, tunnels, drainage pipes, and highway barriers are all made using precast concrete moulds.

- Public Works: Precast concrete is often used for sidewalks, retaining walls, and other public infrastructure projects.

Why Precast Concrete Moulds Are the Future of Construction

The benefits of precast concrete moulds—ranging from high-quality, durable products to faster construction timelines—make them an essential tool in modern construction. Their ability to deliver consistent results, reduce costs, and offer design flexibility is transforming the industry. With sustainability becoming a growing priority, the use of precast concrete moulds ensures that projects are both efficient and environmentally responsible.