Understanding Trunnion Mounted Ball Valves: Design and Functionality

2024-10-31

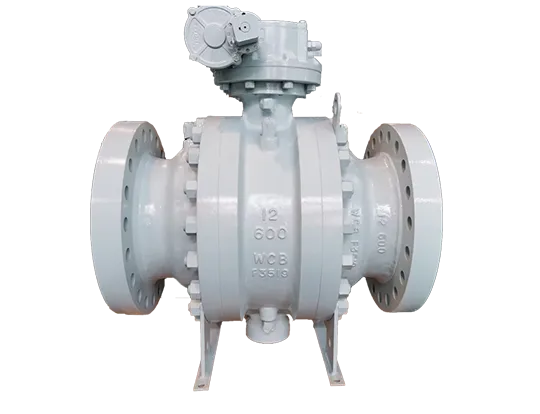

Trunnion mounted ball valves are essential components in various industrial applications, particularly in sectors like oil and gas, water treatment, and chemical processing. These valves offer several advantages over traditional floating ball valves, including enhanced performance and reliability. In this blog post, we will explore the design, functionality, and applications of trunnion mounted ball valves.

1. What Is a Trunnion Mounted Ball Valve?

A trunnion mounted ball valve features a ball that is fixed in place by trunnions (pivot points) at the top and bottom, rather than being supported only by the flow of fluid like a floating ball valve. This design allows the valve to manage high pressure and large diameters more effectively. The trunnion design also helps reduce wear and tear on the valve components, extending its lifespan.

2. Key Components of Trunnion Mounted Ball Valves

- Body: The body is the main structure of the valve, housing the internal components. It can be made from various materials, including carbon steel, stainless steel, and exotic alloys, depending on the application.

- Ball: The ball is the core component that regulates flow. It features a bore through the center, which aligns with the pipeline when the valve is open.

- Trunnions: The trunnions support the ball and allow it to rotate. This fixed position helps maintain alignment and reduces friction during operation.

- Seals: Sealing mechanisms, such as O-rings or soft seals, are used to ensure that no fluid leaks from the valve when it is closed.

- Actuator: Trunnion mounted ball valves can be operated manually or via actuators. Pneumatic, hydraulic, or electric actuators can automate the opening and closing process.

3. Advantages of Trunnion Mounted Ball Valves

- High Pressure and Temperature Ratings: These valves are designed to handle extreme conditions, making them suitable for high-pressure and high-temperature applications.

- Low Torque Requirements: The trunnion design reduces the amount of torque needed to operate the valve, which can lead to less wear on the actuator and longer service life.

- Reduced Seat Wear: Since the ball is supported at both ends, there is less movement against the seats, leading to reduced wear and extended valve life.

- Better Flow Characteristics: Trunnion mounted ball valves provide a more uniform flow profile compared to floating ball valves, improving system efficiency.

4. Applications of Trunnion Mounted Ball Valves

Trunnion mounted ball valves are commonly used in:

- Oil and Gas Industry: They are often employed in pipelines and production facilities for their ability to handle high pressures and corrosive fluids.

- Chemical Processing: The robustness of these valves makes them suitable for controlling the flow of hazardous chemicals.

- Water Treatment: They are used in various stages of water treatment processes, from filtration to distribution.

- Power Generation: Trunnion mounted ball valves are utilized in cooling systems and steam lines, where reliability is critical.

Trunnion mounted ball valves are indispensable in many industrial settings due to their robust design and excellent performance characteristics. Understanding their components, advantages, and applications can help industries select the right valve for their specific needs.