What are the primary components of a bronze bonded grinding wheel

2023-11-04

The primary components of a bronze bonded grinding wheel include:

1. Bronze Matrix (Bonding Material): The bronze matrix, often referred to as the bonding material, is the primary component that holds the grinding wheel together. It provides the structural integrity and maintains the arrangement of abrasive particles on the surface of the wheel. Bronze is chosen for its excellent heat resistance, thermal conductivity, and ability to maintain a secure bond with the abrasive particles.

2. Abrasive Particles: The abrasive particles are the cutting agents that perform the actual grinding action. They are embedded within the bronze matrix in a specific pattern or concentration. The type of abrasive material used can vary and is chosen based on the specific grinding requirements. Common abrasive materials include aluminum oxide, silicon carbide, diamond, and others.

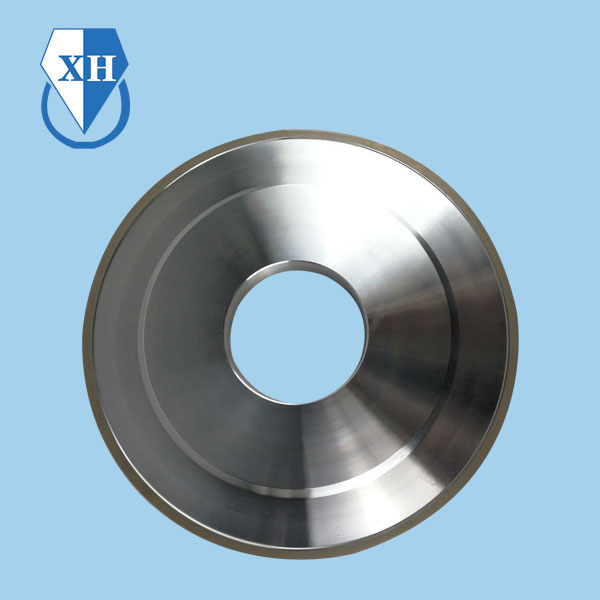

3. Wheel Structure: The wheel structure defines the shape and arrangement of the grinding wheel. Different wheel structures are used for various grinding tasks. Some common structures include flat wheels, cylindrical wheels, cup wheels, and more. The specific structure influences the contact area and cutting action during grinding.

4. Grit Size: Grit size refers to the coarseness or fineness of the abrasive particles used in the wheel. Grinding wheels are available with a range of grit sizes, and the selection depends on the desired surface finish and the material being ground. Coarser grits remove material more aggressively, while finer grits provide a smoother finish.

5. Wheel Hardness: The hardness of the wheel is an important factor in its performance. It is determined by the type and amount of bonding material used. Harder wheels are used for grinding softer materials, while softer wheels are better for grinding harder materials. The hardness affects the rate of material removal and the heat generated during grinding.

6. Wheel Diameter and Thickness: The dimensions of the wheel, including its diameter and thickness, are essential considerations for specific applications. Different wheel sizes are chosen based on the size and shape of the workpiece and the available grinding equipment.

7. Wheel Grade: The grade of the grinding wheel indicates its hardness and the ability to retain the shape during grinding. Wheel grades range from soft (A) to hard (Z), with intermediate grades denoted by letters. The choice of grade depends on the grinding application and the material being worked on.

These primary components work together to define the performance, efficiency, and suitability of a bronze bonded grinding wheel for a specific grinding task. The selection of these components is crucial in achieving the desired grinding results while considering factors like material removal rate, surface finish, and heat generation.